Iron & Steel

Iron & Steel

Solutions / Iron & Steel

The process of iron & steel industry is always divided into raw material production, pellet, sintering, coking, blast furnace processing, steel-making, hot rolling, cold rolling and others. We provide dust removal fan, induced draft fan for sintering, blast furnace combustion fan, boiler waste heat circulation fan, desulphurization and denitration fan and white smoke elimination fan. Besides, renovate and upgrade the traditional industries to improve the fan performance is our latest direction of research and development.

Dust Removal Fan

Large volume, high pressure dust removal fan is adopted, which is special designed with double inlet double drive, high temperature resistant, high efficiency. The transmit medium is dust air or air with particulate matter.

Induced Draft Fan for Sintering

The induced draft fan for sintering is one of the most important supporting machine for the sintering machine, and the mainly transmit medium is sintering flue gas, which contains large volume of dust. It is necessary to use centrifugal fan with large volume and high negative pressure.

Blast Furnace Combustion Fan

In the smelting process, a certain amount of combustive air or oxygen is needed to the blast furnace to increase the furnace temperature. Oxygen is used to improve the efficiency of the smelting process in the iron & steel industry. Large volume centrifugal fan is always used type.

Boiler Waste Heat Circulation Fan

The flue gas after heat exchange is induced into the boiler furnace so that it can be mixed with the high temperature flue gas. The mixed flue gas goes to heat exchange again, which improves the flue gas temperature and boiler efficiency. The main features of the fan are large volume, high pressure centrifugal fan, high temperature resistant. The transmit medium is sintering flue gas for iron ore.

Desulphurization & Denitration Fan

For environmental protection, desulphurization & denitration fan is always use in iron & steel industry. The flue gas produced by the industrial boiler is exhausted after the sulfur dioxide and oxynitride was dealt by the desulphurization and denitration equipment and dust removal equipment. Large volume, high pressure centrifugal fan is always used with high temperature resistant. The fan should satisfy the air quantity requirement at the working condition and it can be working with frequency conversion.

White Smoke Elimination Booster Fan

The flue gas condensation and reheat technology is always adopted for the purpose of white smoke elimination after the process of desulfurization and denitration in iron & steel, power plant, chemical and some other industries. The booster fans are generally used with the heat exchange devices.

Traditional Fan Renovation

Following closely with the national guidelines and policies, to protect environment and reduce carbon emissions, our company develops the special sensor, edge computing devices and the Internet of things system to monitor continuously the fan operating condition to provide customers the fan operation situation and help to improve the fan efficiency so that to promote the reform of fan energy saving in the iron & steel industry.

Successful Cases

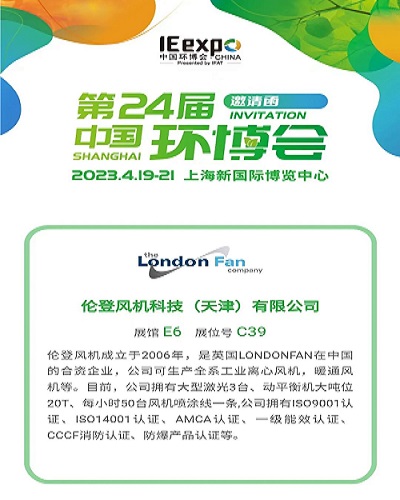

London Fan concerns the environment protection and focus on the heavy industrial fan energy saving and renovation, has developed and participated in many projects in iron & steel industry. The products are high quality, good performance, high efficiency and strong stability, which are widely used in the projects, such as Tianjin Iron & Steel project, Tangshan Medium Thick Plate project, Shaan Steel Group Longsteel Company project, Dazhou Iron & Steel project, Xingyuan iron & steel project and so on. Our fans perform well in each project, which makes us acclaimed by our customers.

Specification of typical cases

Fan Used in One Iron & Steel Company

Contact Us!

Mr. Tan

Professional pre-sales technical consultant, good at fan selection in iron & steel industry, plan of traditional fan energy saving &renovation and related supporting service,

good understanding of the needs of customer, provide personalized customized services. Your contacts and inquiries will be welcomed!

About

London Fan (Tianjin) CO. LTD. 2022

(津ICP备12006605)